Beam windows are a critical part of particle accelerators. As accelerators increase in power and cost, new solutions are needed to find materials that can match the new requirements of future facilities.

In this interview, CERN engineer Nikolina Vejnovic explains the work carried out through the European Union-funded I.FAST project to test two potential base materials – tantalum and T91 steel – for use in new beam window designs.

What was the purpose of the work carried out in the I.FAST project on beam windows – what did you set out to do?

The purpose of Work Package 4.3, initiated by Marcello Losasso from CERN and Marilena Tomut from the GSI Helmholtz Centre for Heavy Ion Research, was to study and develop innovative beam window materials and designs capable of withstanding increased pressure loads and severe beam-induced thermal stresses, in line with the demands of Accelerator-Driven Systems (ADS) and next-generation accelerator facilities.

The work aimed to enhance the safe operation of these facilities by addressing failure risks due to radiation damage and the combined effects of pressure waves and thermal loads.

WP4.3 applied the unique expertise and infrastructure of its partners: the Austrian firm RHP for material procurement and assembly, GSI for ion beam irradiation and characterisation, as well as windows expertise, and CERN for proton irradiation and material testing.

Could you explain briefly the function of a beam window, and say where these components are used?

A beam window is a thin structural barrier that separates a vacuum environment from a region at higher pressure, while allowing particle beams to pass through with minimal interference. Its main function is to maintain the vacuum integrity of the beamline while withstanding mechanical and thermal loads. Beam windows are used in particle accelerators to separate vacuum sectors and are also essential in high-power hadron beam applications, such as Spallation Neutron Sources (SNS) and Accelerator-Driven Systems (ADS), as well as in other nuclear research facilities.

What material(s) are currently used for beam windows? For example, at CERN?

There are two families of beam windows usually adopted: metallic and ceramic ones. Metallic solutions typically include beryllium, titanium, and aluminium alloys. Ceramic solutions are often based on carbon and its allotropes, such as Carbon-Fibre-Reinforced-Carbon (CFC), Glassy Carbon, and graphenic foils. More recent developments successfully tested by colleagues working in CERN’s Vacuum, Surfaces and Coatings group in the Technology department involve thin silicon nitride foils able to sustain very high intensity beams. All these solutions have different physical and technological strength and weaknesses, and the best solution must be tailored case by case depending on the operating conditions and dimensional requirements of the window.

Why did you choose to investigate tantalum and T91 steel as potential new solutions? How could these materials improve on existing beam windows?

We chose to investigate tantalum and T91 steel because they offer promising performance in specific beam conditions over more “traditional” materials.

T91 is a type of martensitic stainless steel known for its high strength, hardness, and good resistance to both wear and corrosion. It performs well at high temperatures, has good thermal conductivity, and resists radiation damage better than many other steels. These properties make it a strong candidate for harsh environments like spallation sources and accelerator-driven systems.

Tantalum, on the other hand, has excellent resistance to corrosion and very high ductility, even at high temperatures. It also has good compatibility with cooling systems and can handle intense radiation without becoming brittle.

These two materials were identified as very promising as base elements for beam windows flange prototypes, to be characterised before and after particle beam irradiation, for potential application in ADS systems.

You already ran one irradiation campaign. What sort of tests did you do?

We carried out an irradiation campaign at CERN at the IRRAD facility where materials were exposed to a proton beam. Before and after irradiation, we performed a series of tests to understand how the microstructure and macroscopic properties of the materials changed. These included optical and scanning electron microscopy (SEM), computed micro-tomography, and various non-destructive techniques. We also measured electrical and thermal conductivity. These tests helped us evaluate how irradiation affects the material’s structure and performance.

What were the results of this campaign?

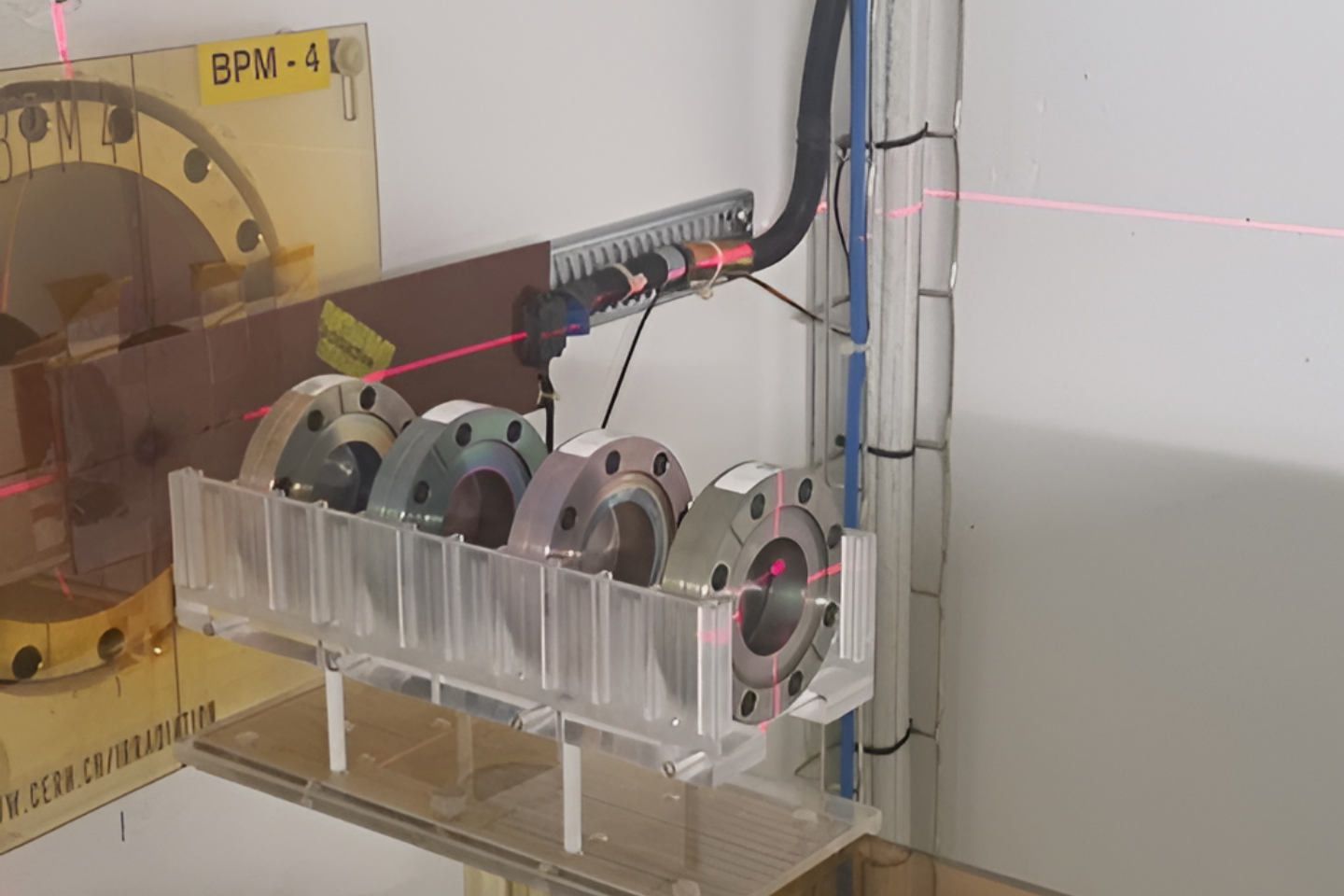

The irradiation campaign provided very useful insights. We produced eight beam window assemblies, four were irradiated, and four were kept as unirradiated references. They were made of stainless steel flanges brazed to tantalum and T91 foils.

From the production and irradiation campaign, we learned several things:

- Brazing remains a challenge for such a thin foil, also due to the mismatch of the thermal expansion coefficient of the brazed materials. Even before irradiation, some samples showed defects and vacuum leaks, about 30% failed leak testing. Improving the brazing process will be a key point.

- Microscopy and tomography revealed clear signs of irradiation at the microstructural level.

- However, macroscopic thermal and electrical properties were not significantly affected by irradiation. In fact, conductivity remained stable or slightly improved, likely due to sample variability rather than a direct effect of the irradiation.

We also plan to collaborate more closely with the CERN FLUKA team and RHP to optimise both the simulation and manufacturing aspects as we move forward.

You have run a second irradiation campaign with 10x higher DPA. Why was this campaign necessary, and when do you expect the results?

The second irradiation campaign was necessary to explore how the materials behave under much higher damage levels. This time, we targeted a dose about 10 times higher than in the first campaign, aiming for displacements per atom (DPA) around 0.01. This allows us to better understand the materials' limits and evaluate their potential use in high activation environments, such as more intense beam facilities.

We also included a new material in this campaign, a 1-micron thick graphenic window to test more innovative solutions.

The irradiation began in April 2024 at CERN’s IRRAD facility and now the samples are in cooldown stage.

Looking forwards, how do you assess the potential of these materials to improve beam windows for accelerator applications, including for industrial applications?

The results so far are promising, and we believe that materials like T91, tantalum, and graphenic foils have strong potential to improve beam windows for accelerator applications but the second campaign would be also useful to check that.

T91 and tantalum combine good mechanical strength, thermal stability, and radiation resistance, which are essential for long-term performance in high-intensity environments. Graphenic materials, although still experimental, show excellent thermal and electrical conductivity, low density, and high flexibility, making them very attractive for future designs.

The I.FAST project received funding from the European Commission’s Horizon 2020 Research and Innovation programme under Grant Agreement No. 101004730. I.FAST aims to enhance innovation in the particle accelerator community, mapping out and facilitating the development of breakthrough technologies common to multiple accelerator platforms. Within CERN, the project is coordinated by the EU Projects Office.